In the ever-evolving world of precision engineering and automation, CNC controllers play a pivotal role in bridging the gap between digital design and physical fabrication. As industries demand higher efficiency and accuracy, the importance of these controllers becomes increasingly evident. They form the backbone of computerized numerical control (CNC) machines, ensuring seamless coordination between various components to produce intricate designs with minimal error margins.

This article delves deep into the world of CNC controllers and their broader implications. It will explore motor position control, the PoKeys57E as a versatile tool for CNC systems, and the role of RC simulator interfaces in enhancing engineering workflows. Whether you’re a seasoned engineer or a curious hobbyist, understanding these components can offer valuable insights into modern automation systems. Each chapter will dissect these topics, shedding light on how they work individually and together to drive technological innovation.

CNC Controllers – The Heart of Precision Machining

A CNC controller is the central hub of a CNC machine, responsible for translating digital instructions into precise movements of motors and other machine components. Acting as the brain of the system, it processes commands from computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control machining tools like mills, lathes, and routers. This vital component ensures that the machine executes every command with accuracy, consistency, and efficiency, making it indispensable in modern manufacturing.

The Functionality of CNC Controllers

At its core, a CNC controller interprets G-code, a standardized programming language that provides instructions for cutting, shaping, or drilling materials. These instructions include parameters such as speed, feed rate, and toolpath. The controller’s ability to manage these variables precisely is what enables CNC machines to create complex parts with exacting tolerances.

Modern CNC controllers are highly sophisticated, equipped with microprocessors that allow real-time adjustments based on sensor feedback. For instance, if a tool encounters unexpected resistance, the controller can adapt its operations to maintain precision while preventing damage to the machine or material.

Types of CNC Controllers

There are several types of CNC controllers, each tailored to specific applications. Open-loop controllers, for example, send commands to the machine without verifying their execution, making them suitable for less complex tasks. On the other hand, closed-loop controllers use feedback systems to ensure that the machine’s actions align with the programmed instructions. This feedback loop enhances accuracy and is especially critical for high-precision tasks.

Hybrid controllers combine the strengths of both open and closed systems, offering flexibility for varied applications. Additionally, advancements in technology have led to the development of PC-based CNC controllers, which leverage the processing power of modern computers to enhance functionality and usability.

Importance of CNC Controllers in Industry

The significance of CNC controllers extends across industries, from aerospace and automotive to healthcare and consumer electronics. Their ability to automate complex processes not only reduces human error but also increases production speed and scalability. Moreover, CNC controllers are integral to achieving consistency in large-scale manufacturing, where even minor deviations can lead to costly consequences.

For small-scale operations and hobbyists, affordable and user-friendly CNC controllers have democratized access to precision machining. Whether crafting intricate jewelry, designing prototypes, or performing routine repairs, a reliable CNC controller ensures that every project meets high-quality standards.

Challenges and Innovations

While CNC controllers have revolutionized manufacturing, they are not without challenges. Factors like compatibility with various software, ease of programming, and real-time monitoring remain areas of focus for developers. Emerging technologies, such as artificial intelligence and IoT integration, are paving the way for smarter, more adaptive controllers. These innovations aim to further enhance efficiency, reduce downtime, and enable remote operation.

In summary, CNC controllers are the driving force behind the precision and efficiency of modern machining processes. By seamlessly orchestrating the movement of motors and tools, they empower industries to push the boundaries of what’s possible in manufacturing. As we move forward, advancements in CNC technology will undoubtedly continue to shape the future of engineering and design.

Motor Position Control – The Precision Behind Every Move

In any CNC system, the ability to achieve precise movements is paramount. This is where motor position control comes into play. It is the mechanism that ensures every motor in the machine moves accurately according to the instructions provided by the CNC controller. From cutting intricate patterns to drilling precise holes, motor position control is the unsung hero that translates digital commands into real-world actions.

What is Motor Position Control?

Motor position control refers to the process of managing and regulating the position of a motor’s shaft. The CNC controller issues commands, specifying how far and how fast the motor should move. Sensors and feedback systems monitor the motor’s position in real time, allowing adjustments to be made to maintain accuracy.

This process often employs various types of motors, including stepper motors and servo motors. Stepper motors excel in precise, incremental movements, making them ideal for applications requiring fine control. Servo motors, on the other hand, are equipped with closed-loop feedback systems, allowing them to achieve higher accuracy and adaptability for complex operations.

The Role of Feedback Systems

The precision of motor position control largely depends on feedback systems. Encoders and resolvers are commonly used to measure the motor’s actual position and send this data back to the CNC controller. Based on this feedback, the controller can correct any discrepancies between the desired and actual positions.

For example, if a milling machine is programmed to cut a specific curve, the feedback system ensures that the motor adjusts its position dynamically, compensating for external factors like material resistance or tool wear. This level of precision is critical, especially in industries like aerospace and healthcare, where minute inaccuracies can have significant consequences.

Applications of Motor Position Control

Motor position control is indispensable in CNC systems, but its applications extend beyond machining. Robotics, for instance, relies heavily on precise motor control for tasks like assembly, welding, and material handling. Similarly, 3D printers use motor position control to build objects layer by layer with remarkable accuracy.

In the realm of automation, conveyor systems use position control to manage the movement of products along assembly lines. Even in everyday devices like camera gimbals and electric vehicles, motor position control ensures smooth and accurate operation.

Enhancing Motor Position Control in CNC Systems

Advancements in motor position control technologies have significantly enhanced the capabilities of CNC machines. Higher-resolution encoders, for instance, enable finer precision by detecting even the smallest movements of the motor shaft. Adaptive algorithms now allow controllers to predict and compensate for potential errors before they occur.

Moreover, the integration of artificial intelligence and machine learning has paved the way for self-optimizing systems. These intelligent controllers can analyze patterns in motor performance, predict maintenance needs, and improve efficiency over time.

Challenges and Future Trends

Despite its critical role, motor position control faces challenges such as vibration, backlash, and thermal drift, all of which can compromise accuracy. Engineers continuously work on designing more robust systems to mitigate these issues. Emerging trends like the use of piezoelectric motors and magnetic encoders promise to further enhance precision and reliability.

As CNC systems become increasingly complex, the demand for advanced motor position control will continue to grow. By ensuring that every movement is executed with pinpoint accuracy, motor position control remains a cornerstone of precision engineering, enabling machines to transform digital blueprints into tangible reality.

PoKeys57E – A Versatile Tool for CNC Systems

As CNC systems evolve, so do the tools that enable their functionality. Among these, the PoKeys57E stands out as a versatile and reliable solution for integrating control and connectivity into CNC machines. This multi-functional device offers advanced features that cater to a wide range of applications, making it a popular choice for engineers, hobbyists, and manufacturers alike.

What is the PoKeys57E?

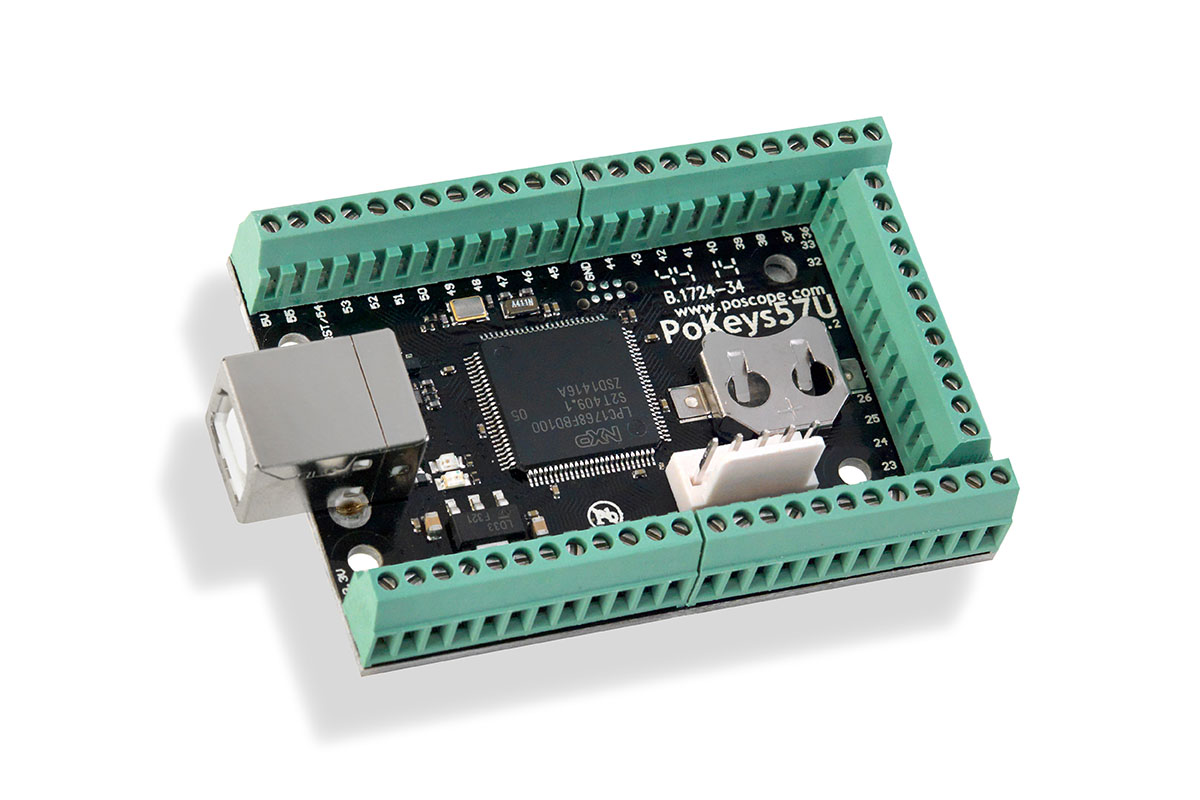

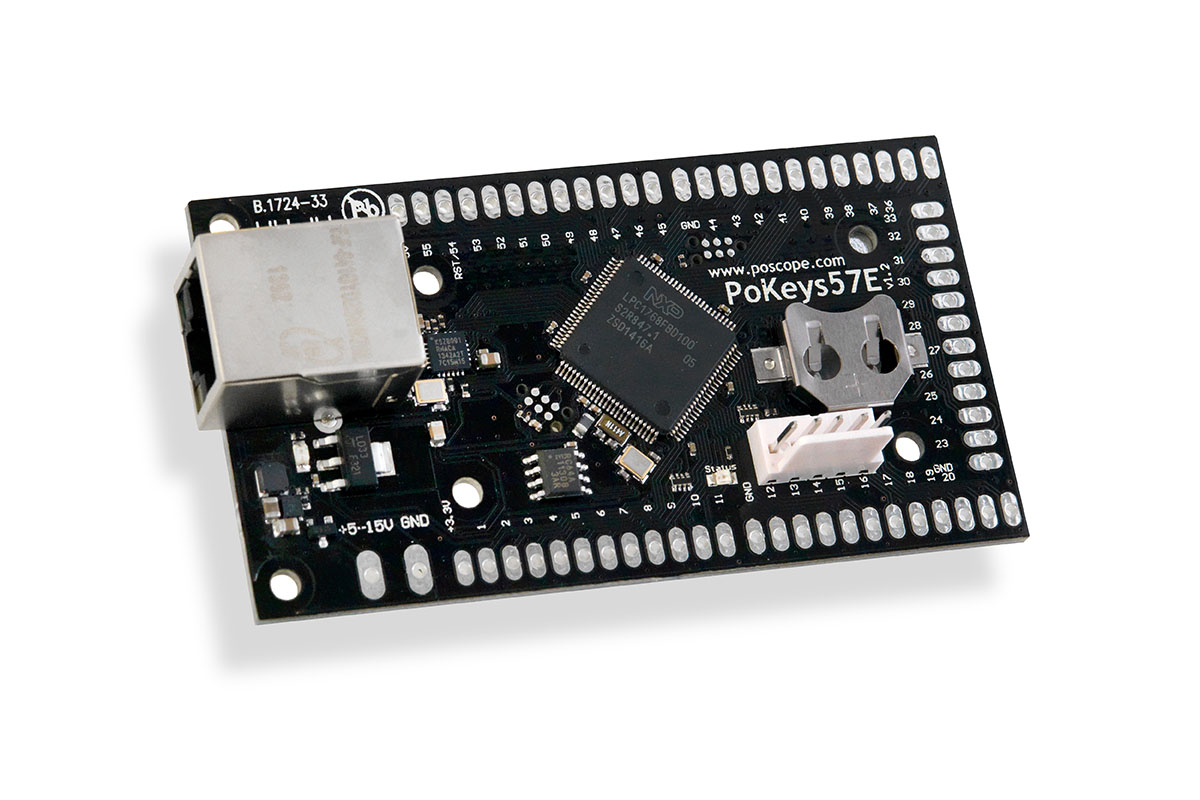

The PoKeys57E is an Ethernet-based device designed for connecting various peripherals and sensors to a computer or CNC system. Manufactured by PoLabs, it is known for its flexibility and ease of use. The device supports digital and analog inputs and outputs, pulse-width modulation (PWM) control, and stepper motor control, making it an all-in-one solution for managing CNC operations.

One of its key advantages is its Ethernet connectivity, which allows for seamless communication between the PoKeys57E and the CNC controller. This enables real-time monitoring and control of the machine from a remote location, a feature that has become increasingly important in modern manufacturing.

Features of the PoKeys57E

The PoKeys57E is packed with features that make it ideal for CNC systems. It can handle up to 55 digital I/O pins, offering ample capacity for integrating switches, sensors, and other components. Additionally, it includes up to 7 analog inputs, allowing for precise measurement and control of variables like temperature and pressure.

Stepper motor and encoder support is another highlight of the PoKeys57E. It enables smooth and accurate motor control, which is essential for achieving the precision required in CNC machining. The device also supports touchscreen displays, making it easier to create user-friendly interfaces for controlling CNC machines.

For developers, the PoKeys57E provides extensive software compatibility. It works with popular CNC software like Mach3 and Mach4, as well as custom-built applications. The accompanying PoKeys configuration utility simplifies setup, allowing users to customize the device for their specific needs without requiring advanced programming skills.

Benefits of Using the PoKeys57E in CNC Systems

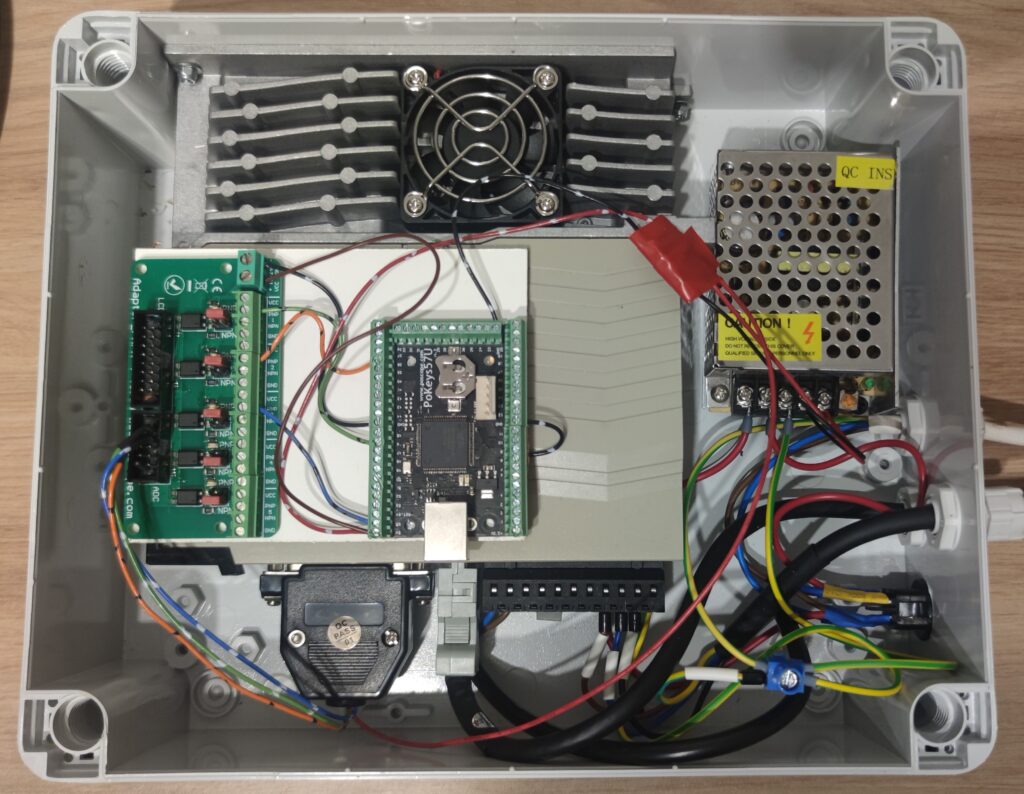

The PoKeys57E offers several benefits that enhance the performance and usability of CNC systems. Its Ethernet connectivity ensures reliable and fast communication, even in environments with high levels of electrical noise. This makes it suitable for industrial settings where signal interference can be a concern.

The device’s modular design allows users to expand and customize their CNC systems as needed. Whether you’re adding more sensors, integrating additional motors, or upgrading software, the PoKeys57E provides the flexibility to adapt to changing requirements.

Another significant advantage is its cost-effectiveness. Compared to traditional CNC controllers and motion control boards, the PoKeys57E offers a high degree of functionality at a relatively low price. This makes it accessible to small businesses and individual hobbyists looking to build or upgrade their CNC setups.

Practical Applications of the PoKeys57E

The PoKeys57E is widely used in a variety of CNC applications. For instance, it can serve as the primary controller for a DIY CNC router or milling machine. In industrial settings, it can function as a supplementary device, managing peripheral components like tool changers, coolant systems, or safety sensors.

Its versatility extends beyond CNC systems. The PoKeys57E is also employed in home automation projects, robotics, and even in creating custom simulators for training and entertainment purposes.

Overcoming Challenges with the PoKeys57E

While the PoKeys57E is a powerful tool, it is not without challenges. Users may encounter difficulties in initial setup, especially if they are unfamiliar with CNC hardware and software integration. However, PoLabs provides comprehensive documentation and support to help users overcome these hurdles.

As technology advances, the PoKeys57E continues to evolve, incorporating new features and capabilities to meet the demands of modern CNC systems. With its robust performance, ease of use, and adaptability, the PoKeys57E has cemented its place as a key component in the world of precision engineering.

RC Simulator Interface – Bridging Precision and Simulation

In the realm of CNC systems and precision control, simulation tools play a vital role in testing, training, and optimizing workflows. One such tool is the RC simulator interface, which connects real-world hardware with virtual environments to simulate complex operations. While traditionally associated with radio-controlled (RC) vehicles and aviation, RC simulator interfaces are increasingly finding applications in engineering and CNC systems, offering a practical way to refine skills and improve system performance.

What is an RC Simulator Interface?

An RC simulator interface is a hardware and software setup that links physical controllers, such as joysticks, transmitters, or input devices, to a simulation environment. This interface replicates real-world conditions in a virtual space, enabling users to practice operations or test configurations without risking damage to actual equipment.

In CNC and precision engineering, RC simulator interfaces can be used to test motor control systems, validate CNC programming, or train operators in machine handling. By simulating real-world dynamics, these interfaces help bridge the gap between design and execution, ensuring that systems perform as intended before they are deployed.

Key Features of RC Simulator Interfaces

RC simulator interfaces are equipped with features that make them highly effective for training and testing. These include:

Real-Time Feedback: The interface provides immediate feedback on user inputs, allowing operators to observe the impact of their commands in a virtual environment.

Wide Compatibility: Many interfaces are compatible with a variety of hardware controllers and software platforms, enabling seamless integration with CNC systems or other precision tools.

Customizability: Users can configure the simulation parameters to match specific system requirements, such as motor speeds, toolpaths, or environmental conditions.

For example, an RC simulator interface connected to a CNC controller might simulate the movement of motors and the machining process. This allows operators to refine G-code programming, test motor position control, and troubleshoot potential issues without engaging the actual machine.

Benefits of RC Simulator Interfaces in CNC Applications

The adoption of RC simulator interfaces in CNC workflows offers numerous advantages.

Risk Reduction: By simulating operations, engineers and operators can identify and address potential issues before they cause damage to equipment or materials.

Cost Efficiency: Simulations eliminate the need for extensive trial-and-error on physical systems, reducing wear and tear on machinery and saving resources.

Enhanced Training: For new operators or hobbyists, RC simulator interfaces provide a safe environment to learn and experiment without the fear of making costly mistakes.

Additionally, RC simulator interfaces are invaluable for prototyping and system development. Engineers can test motor configurations, validate software integration, and optimize machine performance in a controlled setting.

Integration with CNC Systems

RC simulator interfaces can be seamlessly integrated with CNC controllers like the PoKeys57E, enhancing their functionality. For instance, by connecting the PoKeys57E to an RC simulator, users can simulate motor position control and other CNC operations in real time. This combination provides a powerful platform for testing and refining complex workflows.

Furthermore, RC simulator interfaces are increasingly being used with virtual reality (VR) technologies, creating immersive training experiences. In these setups, operators can interact with a simulated CNC system in a 3D environment, gaining hands-on experience without physical limitations.

Challenges and Future Directions

While RC simulator interfaces offer significant benefits, they also present challenges. Ensuring compatibility between the interface, CNC hardware, and simulation software can be complex, requiring careful configuration. Additionally, the accuracy of the simulation depends on the quality of the interface and the software used, which can vary widely.

Looking ahead, advancements in machine learning and artificial intelligence promise to further enhance RC simulator interfaces. These technologies could enable adaptive simulations that respond dynamically to user inputs, providing even more realistic training and testing environments.

A Tool for Precision and Progress

The RC simulator interface is more than a tool for hobbyists; it is a critical resource for precision engineering and CNC operations. By enabling risk-free experimentation, cost-effective testing, and immersive training, it empowers users to push the boundaries of what’s possible. As these interfaces continue to evolve, they will undoubtedly play an increasingly vital role in shaping the future of CNC systems and automation.

The Interconnected World of CNC Precision and Innovation

The modern landscape of precision engineering is a testament to the seamless integration of advanced tools and technologies, with CNC controllers at its core. These controllers act as the brain of CNC systems, orchestrating the intricate dance of motors, tools, and materials to create products with unparalleled accuracy. Surrounding this central component are technologies like motor position control, the versatile PoKeys57E device, and RC simulator interfaces, each playing a crucial role in enhancing functionality, precision, and user experience.

Motor position control ensures that every movement of the CNC machine is executed with exacting precision, laying the foundation for reliable and efficient machining. The PoKeys57E, with its flexibility and robust feature set, serves as a powerful tool for customizing and optimizing CNC systems for diverse applications. Meanwhile, RC simulator interfaces bridge the gap between real-world operations and virtual testing, offering safe and cost-effective solutions for training and workflow validation.

Together, these components form a cohesive ecosystem that drives innovation across industries, from aerospace to manufacturing and beyond. As technologies continue to advance, the synergy between CNC controllers, motor control systems, and simulation tools will only deepen, paving the way for smarter, faster, and more adaptive automation systems.

Whether you’re a seasoned professional or a budding enthusiast, understanding these interconnected elements offers valuable insights into the world of precision engineering. By leveraging the capabilities of CNC controllers and their supporting technologies, we can continue to push the boundaries of creativity and innovation, shaping a future defined by accuracy, efficiency, and limitless possibilities.